During production, simply install the detector after the required process to achieve continuous surface quality monitoring of the wire. This installation method allows real-time monitoring of the wire's surface quality, enabling the immediate identification and correction of any potential defects, ensuring the product meets strict quality standards. This not only enhances production efficiency but also effectively reduces defect rates, bringing significant economic benefits to the company.

Even in high-speed production environments of up to 1500 meters per minute, the detector still delivers real-time and precise defect detection, making it a powerful monitoring tool for both on-site and laboratory quality control.

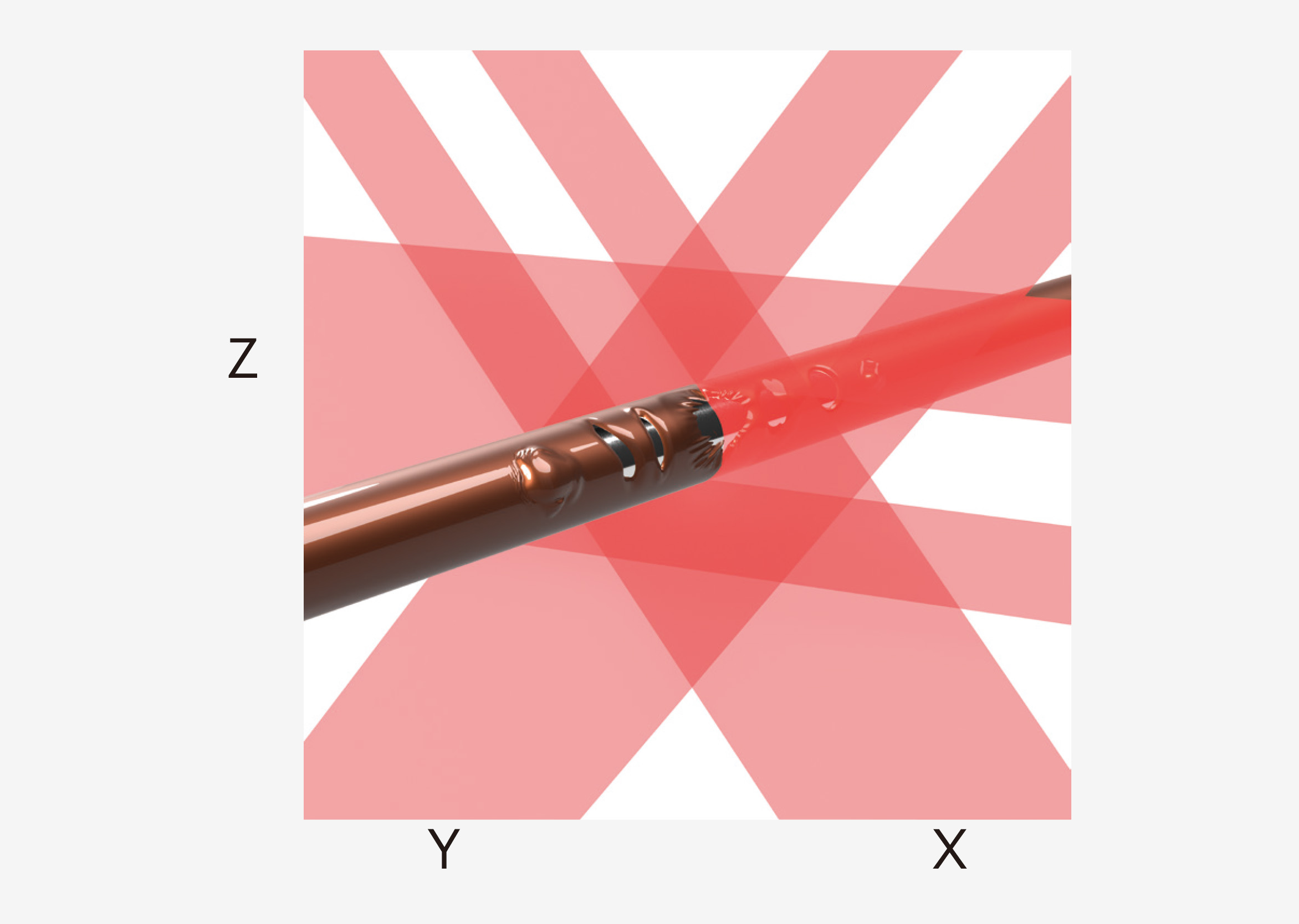

High-Speed Three-Axis Detection Mode

The high-speed three-axis detection mode significantly broadens the coverage area of the measured object, making the detection process more refined, accurate, and comprehensive, effectively improving the overall quality and effectiveness of the detection.